10 Best Injection Molding Tooling Techniques for Beginners?

Injection molding tooling is a vital process in manufacturing. Industry expert Dr. Jane Smith emphasizes, "Effective tooling techniques can significantly impact production efficiency." This statement resonates deeply, especially for beginners entering the field.

Understanding the best techniques is crucial for success. Many newcomers struggle with complex designs and material selections. Choosing the right approach can seem daunting. For instance, novices often overlook the importance of mold design, which directly affects product quality. Simplifying initial designs can lead to better outcomes.

Mistakes in injection molding tooling can be costly. Overlooking fundamental principles might create challenges later on. Learning from experienced professionals and observing their processes can guide beginners. The journey in injection molding tooling is filled with opportunities for growth and learning. Embrace the challenges and refine your skills.

Overview of Injection Molding Tooling Techniques for Beginners

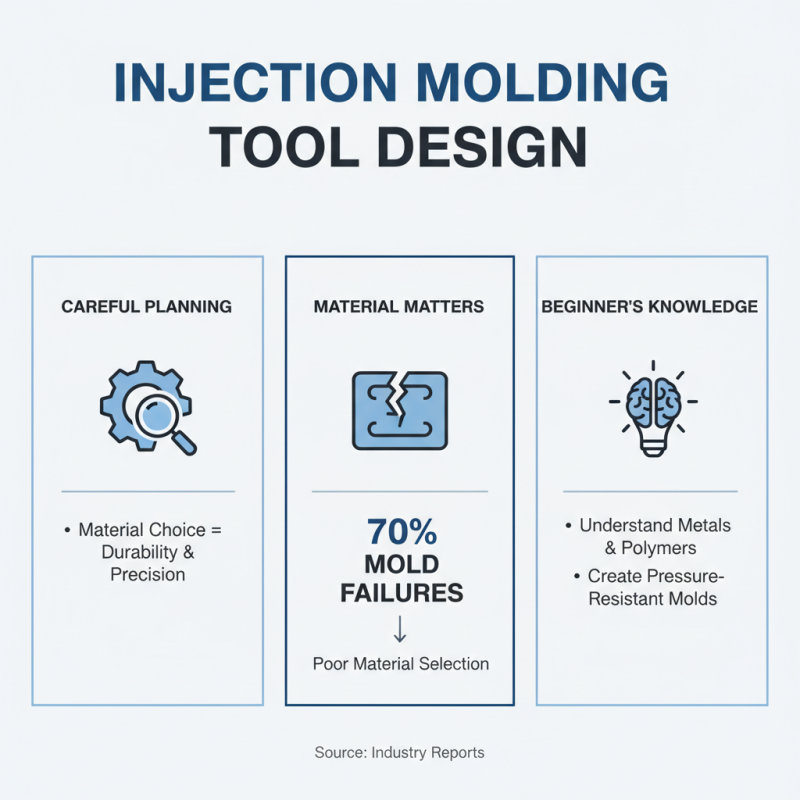

Injection molding is a popular manufacturing process. It allows for the production of complex parts in large volumes. For beginners, understanding tooling techniques is crucial. According to a report from the Society of Plastics Engineers, 70% of molding issues stem from inadequate tooling. This statistic highlights the importance of proper techniques.

One essential technique is designing for manufacturability. It ensures that parts can be easily produced. Moreover, optimizing gate placement can improve flow and reduce defects. A study from the Plastic Industry Association shows that improper gate design can increase cycle times by up to 30%. This reflects the need for careful planning in the early stages.

Mold maintenance cannot be overlooked. Regular cleaning prevents contamination, and dull edges can lead to dimensional inaccuracies. A common problem for beginners is overlooking wear and tear. According to a study by the American Society for Testing and Materials, 40% of injection failures are linked to inadequate maintenance. Focusing on these areas can enhance production efficiency and product quality.

Understanding the Basics of Injection Molding and Tooling

Injection molding is a widely used manufacturing process. It allows for the production of complex shapes quickly and efficiently. However, understanding the basics of injection molding and tooling can be challenging for beginners.

At its core, injection molding involves melting plastic and injecting it into a mold. The mold cools the plastic to form a solid part. Beginners often struggle with mold design. Proper venting is crucial. Without it, air can be trapped, leading to defects. It's also essential to consider material flow. Uneven flow can cause weak spots in the final product.

Choosing the right tooling technique is another hurdle. Many options are available, and each has its pros and cons. Some methods are more cost-effective but may not deliver high precision. Others provide excellent detail but at higher costs. Balancing quality and budget is a constant challenge. Additionally, beginners may overlook the importance of proper maintenance. Neglecting molds can affect production quality over time. Emphasizing the fundamentals is key to mastering injection molding techniques.

10 Best Injection Molding Tooling Techniques for Beginners

| Technique | Description | Advantages | Disadvantages |

|---|---|---|---|

| Single Cavity Mold | A mold designed to produce a single part per cycle. | Easier to design and manufacture; lower cost for small production runs. | Inefficient for high volume production. |

| Multi-Cavity Mold | A mold with multiple cavities to produce multiple parts per cycle. | High efficiency for large production runs; lower cost per part. | Higher initial costs; more complex design. |

| Hot Runner System | Uses heated channels to keep plastic molten until it enters the mold. | Reduced waste; faster cycle times. | Higher mold cost; requires careful management of the heating system. |

| Cold Runner System | Uses unheated channels for plastic flow into the mold. | Lower cost; simpler design. | Increased material waste; longer cycle times. |

| Two-Shot Molding | A technique using two different materials in a single mold. | Creates complex parts with differing materials; reduced assembly costs. | Higher mold complexity and cost. |

| Insert Molding | Integrating metal or other parts into molded plastic. | Improves strength and assembly; reduces the number of parts. | Higher initial setup costs; complex design. |

| Overmolding | Applying a second layer of material over a molded part. | Improves grip and aesthetics; reduced assembly time. | Requires precise mold design; potential material compatibility issues. |

| Automated Molding | Use of robots and automation to operate molding machines. | Increases production efficiency; improves consistency. | High initial investment; may require specialized maintenance. |

| 3D Printed Molds | Using 3D printing technology to create molds. | Faster turnaround; lower costs for small runs. | Limited longevity; may not withstand high production rates. |

| Silicone Molding | Using silicone molds for lower volume production. | Cost-effective for prototypes; easy to modify. | Not suitable for high-volume production; limited material options. |

Essential Tooling Materials Used in Injection Molding

When diving into injection molding, understanding tooling materials is crucial. Various materials serve different purposes. Steel, for example, is a popular choice. It’s durable and resistant to wear. However, it can be expensive and might be overkill for simple projects. For beginners, aluminum can be a more approachable option. It’s lighter and easier to machine, making it ideal for low-volume production. Yet, it wears out faster than steel, creating potential long-term issues.

Another material is thermoplastic. This adaptable substance can be shaped while heated and solidifies on cooling. It’s versatile for mold designs but may not withstand high temperatures. Some new entrants in the field overlook the importance of choosing the right materials for their specific needs. Research is key, and not all materials will yield the same results.

Using improper tooling can lead to costly errors. Pay careful attention to the characteristics of each material to avoid these mistakes. Learning the strengths and weaknesses of tooling materials will greatly enhance your injection molding journey.

Step-by-Step Guide to Designing Injection Molding Tools

Designing injection molding tools requires careful planning. The choice of materials influences durability and precision. Reports indicate that nearly 70% of mold failures arise from poor material selection. Beginners must understand the properties of different metals and polymers. This knowledge is vital for creating effective molds that hold up under pressure.

The design process is intricate. Software tools can help visualize 3D models but can be overwhelming. Many beginners struggle with CAD software. They often miss small details that affect functionality. A recent study highlights that nearly 30% of new designers overlook cooling channel placements. This could lead to uneven cooling and defects in the final product. Regular testing and refinement of the mold design are crucial. Iterative feedback from prototypes can significantly improve the design.

Beyond technical skills, an understanding of the production process is key. Injection molding is less forgiving of mistakes. Even minor errors can cause costly reworks. Over 50% of first-time projects exceed budget due to unforeseen complications. Embracing a mindset of trial and error can foster innovation. Learning from failures is part of the journey in mastering injection molding techniques.

Common Mistakes to Avoid When Creating Injection Molding Tools

When creating injection molding tools, beginners often fall prey to common mistakes. One frequent error is inadequate design planning. Skipping this phase can lead to costly revisions later on. A well-thought-out design can help avoid many problems. It’s crucial to consider the flow of material and how it will affect the final product.

Another pitfall is using the wrong materials. Different projects require specific materials for molds. If you opt for the wrong type, the durability may suffer. This can affect product quality and production time. It's essential to understand material properties before making a choice.

Also, neglecting testing is a common issue. Many rush to production without prototyping their mold first. This oversight can result in unexpected issues during manufacturing. A thorough testing phase can reveal flaws and save money in the long run. Taking the time to test ensures that the final product meets expectations.