2026 Best Injection Molded Plastic Parts for Efficient Manufacturing Solutions?

In the world of manufacturing, the importance of injection molded plastic parts cannot be overstated. These parts drive innovation and efficiency across various industries. According to Mark Thompson, a leading expert in plastic manufacturing, "The right injection molded plastic parts can transform product design and production speed." This statement resonates with many companies seeking to optimize their manufacturing processes.

However, achieving optimal results involves challenges. Many manufacturers overlook critical factors such as the choice of materials and design intricacies. Poorly designed injection molded plastic parts can lead to costly defects and production delays. Furthermore, the balance between cost and quality often sparks debate within organizations. It is crucial to evaluate these trade-offs thoroughly.

As we look ahead to 2026, the future of injection molded plastic parts is promising yet complex. Continuous advancements in technology present opportunities for improvement. Yet, they also require manufacturers to adapt or risk falling behind. Going forward, the industry must reflect on past practices to truly innovate and excel.

2026 Trends in Injection Molded Plastic Parts for Manufacturing

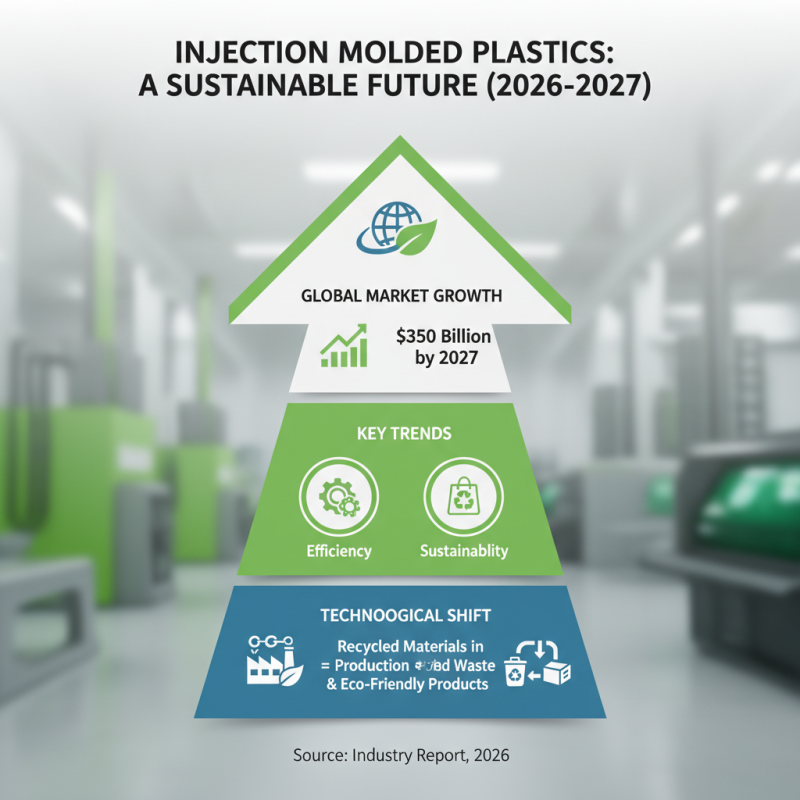

The landscape of injection molded plastic parts is shifting rapidly in 2026. Manufacturers are adapting to trends that emphasize efficiency and sustainability. A recent industry report indicates that the global injection molding market could reach $350 billion by 2027. With technological advancements, companies are now focusing on utilizing recycled materials in production. This shift not only reduces waste but also meets rising consumer demand for eco-friendly products.

Tips: Explore local suppliers to find sustainable material options. Investigate how your production waste can be minimized.

Another trend is the integration of Industry 4.0 technologies. Automation and IoT are enhancing production processes. Real-time data tracking can improve quality control and reduce errors. Yet, not all manufacturers are equipped for this transition. The initial investment can be daunting, and some may overlook the long-term benefits. Effective training for staff is also crucial to fully leverage new technologies.

Tips: Prioritize employee training to ensure a smooth transition. Assess your current processes before adopting new technologies.

Key Benefits of Using Injection Molded Plastic in Production

Injection molded plastic parts are pivotal for modern manufacturing. Reports indicate that the global plastic injection molding market is projected to reach $440 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.5%. The efficiency of this manufacturing process is undeniable. It allows for high-volume production with minimal waste, thanks to precise material usage.

One key benefit of injection molded plastics is their versatility. Diverse industries, from automotive to consumer goods, utilize this technology. Parts can be engineered to meet specific performance criteria. For instance, advancements in materials enhance durability. However, the challenge often lies in balancing cost with quality. It remains crucial to evaluate material properties to ensure optimal production.

Moreover, the speed of production is notable. Molding cycles can be as quick as 15 to 60 seconds, drastically reducing lead times. Yet, it's essential to assess the environmental impact of plastic waste. Sustainable practices are gaining traction, pushing manufacturers to explore biodegradable options. Efficiency must align with responsibility, prompting industry reflection on future practices.

Innovative Materials for Injection Molded Plastic Parts in 2026

The landscape of injection molded plastic parts is evolving rapidly. In 2026, innovative materials are leading this change. Biodegradable plastics are gaining traction. They offer a sustainable alternative to traditional polymers. These materials can decompose naturally, reducing environmental impact. However, they may not perform as well under high-stress conditions.

Another emerging trend is the use of advanced composites. These materials combine plastics with fibers or other elements, enhancing strength and durability. They are particularly useful for complex designs requiring precision. Still, the production process can be challenging. It often demands specialized machinery and expertise, which not all manufacturers possess.

Reinforced plastics are also on the rise. They feature enhanced toughness ideal for harsh environments. Yet, the cost can be prohibitive for some applications. Companies must weigh advantages against expenses. This balance is crucial for effective decision-making in manufacturing. Exploring these innovative materials brings both opportunities and challenges. Design and practicality must align as products advance.

2026 Best Injection Molded Plastic Parts for Efficient Manufacturing Solutions

| Material Type | Common Applications | Advantages | Disadvantages | Cost per Kg (USD) |

|---|---|---|---|---|

| ABS | Consumer Electronics, Toys | High impact resistance, easy to process | Low heat resistance | 3.00 |

| Polypropylene (PP) | Packaging, Automotive Parts | Excellent chemical resistance, lightweight | Low strength | 2.00 |

| Polycarbonate (PC) | Safety Glasses, Medical Devices | High impact resistance, optical clarity | Expensive, can yellow over time | 6.00 |

| Nylon (PA) | Gears, Automotive Components | High strength, good fatigue resistance | Absorbs moisture | 4.00 |

| Polystyrene (PS) | Disposable Cutlery, DVD Cases | Low cost, easy to mold | Brittle, low impact strength | 1.80 |

Sustainable Practices in Injection Molding for Eco-Friendly Solutions

Sustainable practices in injection molding are vital for eco-friendly manufacturing. The industry faces challenges in reducing waste and energy consumption. Many companies are exploring renewable materials, such as bioplastics, to replace traditional petroleum-based options. These materials often require adjustments in manufacturing processes, which can initially seem daunting.

Energy efficiency is another critical area. Advanced technologies help to minimize energy usage during production. For example, machines with better insulation or hybrid designs can reduce electricity consumption. Yet, transitioning to these technologies requires investment and planning, and not all manufacturers are ready for this shift.

Recycling is a significant aspect of sustainability. Some facilities are now using recycled plastics in their injection molding processes. However, the quality of these materials can sometimes be inconsistent. This inconsistency can affect production outcomes and product integrity. Companies must continuously evaluate their processes to find a balance between sustainability and product performance.

Sustainable Practices in Injection Molding for Eco-Friendly Solutions

Challenges and Solutions in Injection Molded Plastic Manufacturing

The journey of injection molded plastic manufacturing is fraught with challenges. One common issue is material consistency. Variations in raw materials can lead to defects. This affects product quality and increases waste. Detecting inconsistencies requires meticulous quality control. Often, teams struggle with this, leading to greater inefficiencies.

Another challenge is cycle time. Shortening it can boost productivity but may compromise quality. Many manufacturers find it hard to strike the right balance. Rushing through each stage often leads to errors. A clear understanding of process optimization is vital but frequently overlooked.

Finally, employee training is critical. Skilled workers can mitigate many problems. However, finding the time and resources to train effectively is an ongoing struggle. Companies must reflect on their training programs. Addressing these gaps can significantly enhance overall performance.